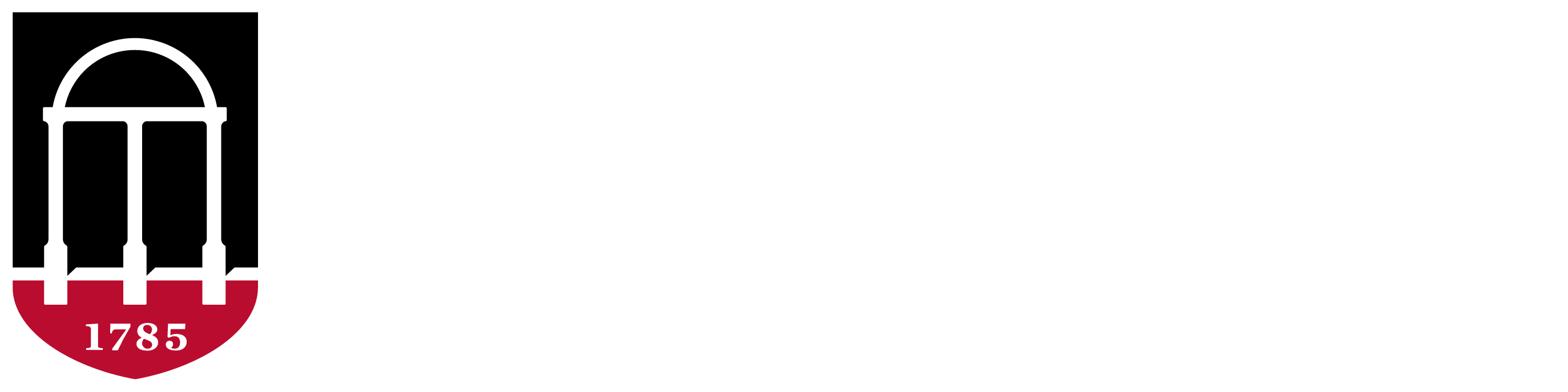

From left, undergraduate students Nakyia Lezin-Bessard, Satchit Seth and Wissam Fekir test the calibration of the Unitree Go1 dog robot as part of their work on the VIPR poultry team. (Photo by Lavi del Carmen Astacio)

From left, undergraduate students Nakyia Lezin-Bessard, Satchit Seth and Wissam Fekir test the calibration of the Unitree Go1 dog robot as part of their work on the VIPR poultry team. (Photo by Lavi del Carmen Astacio)

Building Breakthroughs

At UGA, student researchers build the future of agriculture through robotics and solar innovation

By Jordan McLaughlin

Photos by Sean Montgomery and Lavi del Carmen Astacio

In a world where food systems, energy production and environmental health are deeply connected, the VIPR program at UGA empowers students to bridge those fields through research in robotics, agrivoltaics and ecological monitoring.

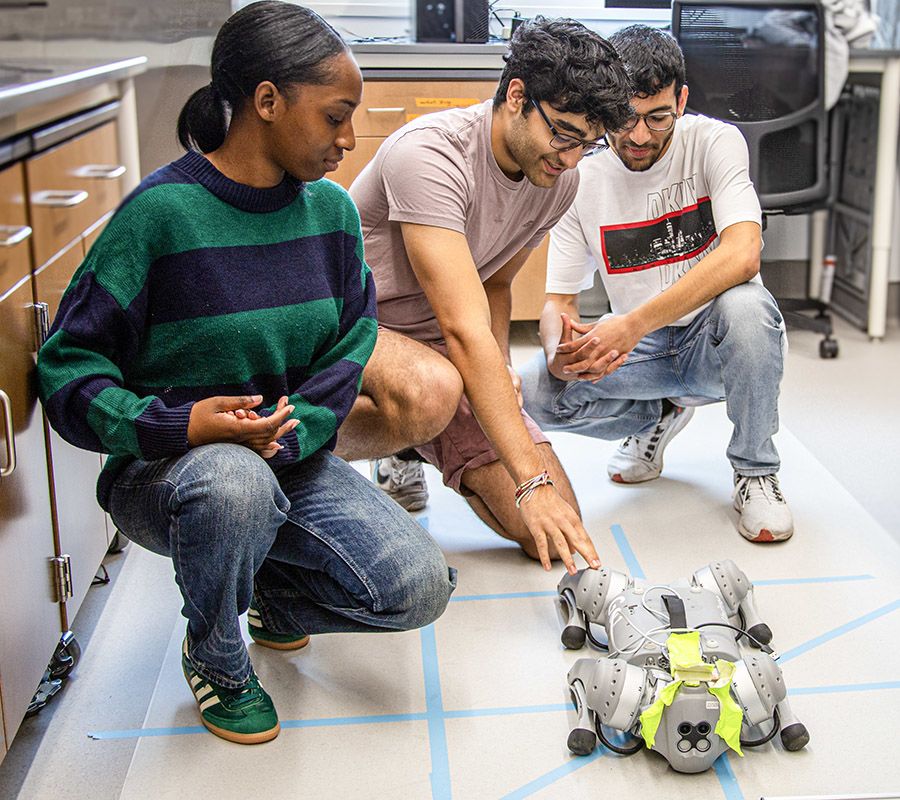

At UGA’s Poultry Science Building, Nakyia Bessard-Lezin tests a pair of kitchen tongs — a creative solution for a pressure-sensitive robotic egg gripper — as part of her research with the VIPR program. When high-tech sensors didn’t fit, she improvised, proving that sometimes innovation starts in unexpected places. (Photo by Lavi del Carmen Astacio)

At UGA’s Poultry Science Building, Nakyia Bessard-Lezin tests a pair of kitchen tongs — a creative solution for a pressure-sensitive robotic egg gripper — as part of her research with the VIPR program. When high-tech sensors didn’t fit, she improvised, proving that sometimes innovation starts in unexpected places. (Photo by Lavi del Carmen Astacio)

Under the hum of fluorescent lights in a lab in the new University of Georgia Poultry Science Building, Nakyia Bessard-Lezin stood staring at a robotic arm that just wasn’t going to work.

The mini GelSight tactile sensors she had planned to mount were too wide, their bulky frames leaving no room for the machine to do what it was designed to do: gently grip and lift a fragile egg without cracking it.

So Bessard-Lezin, an electrical and electronics engineering major, did what no textbook had prepared her for — she raided the kitchen. Swapping lab equipment for a pair of metal tongs, she improvised her own robotic gripper to test egg-handling pressure.

Bessard-Lezin’s low-tech hack is part of a high-tech push in agricultural robotics under the Vertically Integrated Projects for Research (VIPR) program out of UGA’s Office of Instruction. The program has brought together undergraduate students from across the university to work in large-scale, multidisciplinary research alongside faculty and graduate students since 2017. Beginning in fall 2024, the program expanded to include precision agriculture.

VIPR, administered through the Center for Undergraduate Research Opportunities, is based on a global model for collaborative research from the VIP Consortium. It brings together interdisciplinary teams — comprised of undergraduate researchers, faculty mentors, graduate students and postdoctoral associates — to advance research and provide hands-on opportunities for aspiring scientists.

Through a collaboration between the College of Agricultural and Environmental Sciences, the College of Engineering and the Odum School of Ecology, VIPR piloted two new research projects in fall 2024: agricultural robotics and agrivoltaics.

Sheep, bees and solar energy

Bodie Pennisi, the Vincent J. Dooley Professor of Horticulture in the Department of Horticulture and statewide UGA Cooperative Extension landscape specialist, and Jason Schmidt, a professor in the Department of Entomology, kicked off the first semester of the agrivoltaics VIPR program by getting students out of the lab and into the field.

The team visited Silicon Ranch's Houston Solar Project in Elko, Georgia, where hundreds of sheep live amongst 800 acres of solar panels, to observe the integration of livestock systems with a solar power facility that serves more than 11,000 local households. They also visited a 7-acre solar farm in Plains, Georgia, where UGA researchers have studied both sustainable energy and ecosystem health since 2020.

Associate Professor Jason Schmidt and VIPR student Kariana Colon measure ecosystem diversity beneath solar panels at the Carter Foundation’s agrivoltaics site in Plains, Georgia, where UGA has been studying ecosystem services since 2020. (Photo by Bodie Pennisi)

Associate Professor Jason Schmidt and VIPR student Kariana Colon measure ecosystem diversity beneath solar panels at the Carter Foundation’s agrivoltaics site in Plains, Georgia, where UGA has been studying ecosystem services since 2020. (Photo by Bodie Pennisi)

“These two sites offered an excellent opportunity for students to visualize how the system works and some of the challenges and questions we are trying to address,” Pennisi said. “It is important for the students to have a grounded understanding of a complex system, from a scientific and a social perspective.”

During site visits, students gained firsthand experience with agrivoltaics — the practice of combining agriculture with solar energy production. The students’ VIPR research aims to optimize systems integrating crops, ruminants and pollinator habitats with solar arrays, maximizing land-use efficiency, providing farmers with an additional revenue stream from renewable energy, and creating opportunities for aspiring farmers. This approach has been found to improve soil moisture retention and reduce heat stress on plants and animals.

Jason Schmidt, Bodie Pennisi, Dean Nick T. Place and Jordan Powers pose for a photo with Silicon Ranch representatives at Silicon Ranch solar farm in Elko, Georgia. (Photo by Sean Montgomery)

Jason Schmidt, Bodie Pennisi, Dean Nick T. Place and Jordan Powers pose for a photo with Silicon Ranch representatives at Silicon Ranch solar farm in Elko, Georgia. (Photo by Sean Montgomery)

“In Jeff Davis County we’ve developed solar facilities on land that was previously conventional agricultural fields. They were in a cotton-peanut-corn rotational regimen for decades — not a fantastic place for wildlife. We’ve come back in and established perennial, deep-rooted vegetation and, anecdotally, we’ve seen the quail population explode — but we have not quantified that impact scientifically. Doing that in partnership with UGA VIPR research is going to be beneficial and answer a lot of questions that we, and the communities where we operate, would like answers for.”

— Loran Shallenberger, senior director of regenerative energy operations at Silicon Ranch

“There’s a lot of mystery and misconception about the impact of solar,” said Matt Beasley, chief commercial officer at Silicon Ranch. “We believe that land that goes into solar development does not have to be taken out of agricultural production. We can harvest renewable electrons and agricultural products on the same property.”

The agrivoltaics VIPR leadership team is seeking long-term funding from the U.S. Department of Energy and the National Renewable Energy Laboratory for agrivoltaics research and education, with a focus on undergraduate research.

The team is also collaborating with the Georgia Public Service Commission and local utility companies to establish research sites in solar arrays, providing field education sites for students. The Odum School of Ecology is working with three solar energy companies on research and training, including Silicon Ranch, a founding partner of the Agrivoltaics Initiative at Odum.

Autonomous weed pulling

Led by Assistant Professor Sultan Mahmud, the VIPR agricultural robotics team is working to solve a weedy problem that has plagued cotton farmers as long as cotton has been cultivated.

In Georgia’s vast cotton fields, weeds aren’t just an inconvenience — they’re a costly threat. Weeds steal water, nutrients and sunlight from slow-growing cotton seedlings and can slash yields by up to 90% if left unchecked. For decades, Georgia farmers have fought back with herbicides, but overuse has led to the rise of resistant weed species. The industry faces mounting concerns over environmental impact and rising costs, pushing researchers to find solutions.

Mahmud, whose work in the Department of Plant Pathology focuses on precision crop protection, is supervising the student team’s design and development of an autonomous weed-pulling robot to tackle the problem head-on. The students hope to reduce reliance on chemical weed control while minimizing soil disruption caused by mechanical methods.

“Poor weed management during harvest can slow down operations by causing mechanical issues with cotton pickers and introducing weed debris that degrades fiber quality,” said Rhys DeLoach, an agricultural engineering major and a member of the agricultural robotics team.

Rhys DeLoach, Muneeb Elahi Malik and Sultan Mahmud pose with three robotics projects outside of the Miller Plant Sciences building. (Photo by Sean Montgomery)

Rhys DeLoach, Muneeb Elahi Malik and Sultan Mahmud pose with three robotics projects outside of the Miller Plant Sciences building. (Photo by Sean Montgomery)

The stakes are high. Cotton is Georgia’s fourth-largest agricultural commodity, contributing $1.3 billion to the state’s economy in 2024. Traditionally, farmers have relied on genetically modified cotton varieties that tolerate herbicides like glyphosate (Roundup), allowing them to kill weeds without harming their crops. But as herbicide-resistant weeds spread, the industry faces mounting concerns, including potential damage to nontarget plants and soil health.

Some farmers have turned to mechanical weed removal, such as tilling or hand-pulling, but frequent tilling can degrade soil structure, leading to erosion and reduced water retention. Labor-intensive solutions are also time-consuming and expensive.

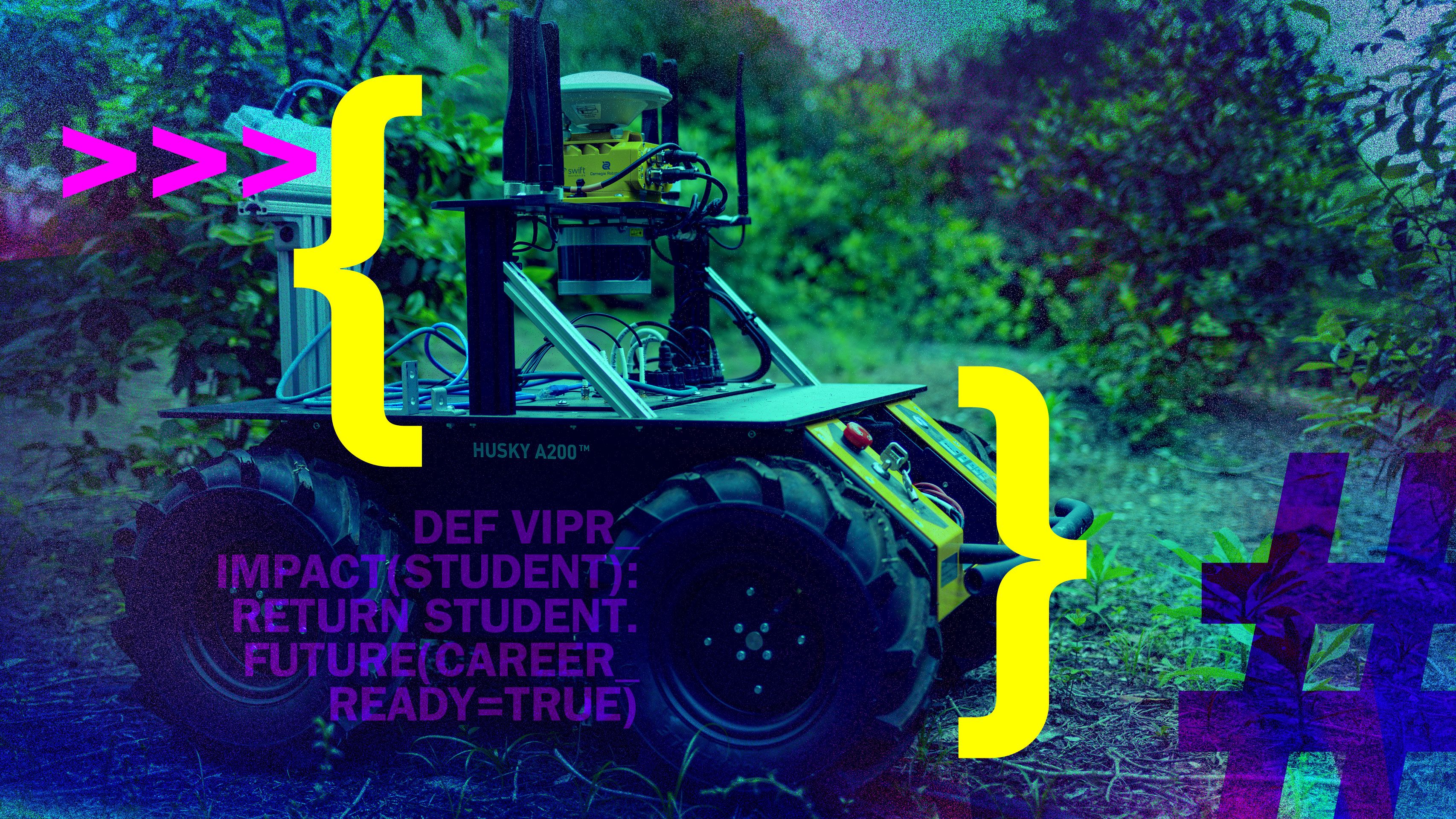

VIPR’s agricultural robotics team is hard at work on a better solution. Built on the Husky A200 unmanned ground vehicle (UGV) platform, their autonomous system blends the precision of mechanical weeding with the efficiency of automation. Unlike chemical methods or traditional tilling, it doesn’t contribute to herbicide resistance or disturb the soil. With the ability to operate continuously, it offers a cost-effective alternative to manual labor.

Once fully developed, the robot will leverage machine vision to distinguish weeds from cotton plants. Using a pair of robotic arms, it will pluck weeds from crop rows, offering farmers a high-tech, sustainable solution to one of cotton production’s most persistent challenges.

From left, Angilbert Baraka, Gaurish Vasireddy and Jordan McLaughlin — of the agricultural robotics team in Guoyu Lu’s engineering VIPR 2601 class — use thermal and digital imaging to study rose rosette disease on plants at the UGA Trial Gardens. (Photo by Lavi del Carmen Astacio)

From left, Angilbert Baraka, Gaurish Vasireddy and Jordan McLaughlin — of the agricultural robotics team in Guoyu Lu’s engineering VIPR 2601 class — use thermal and digital imaging to study rose rosette disease on plants at the UGA Trial Gardens. (Photo by Lavi del Carmen Astacio)

A hot take on detecting disease

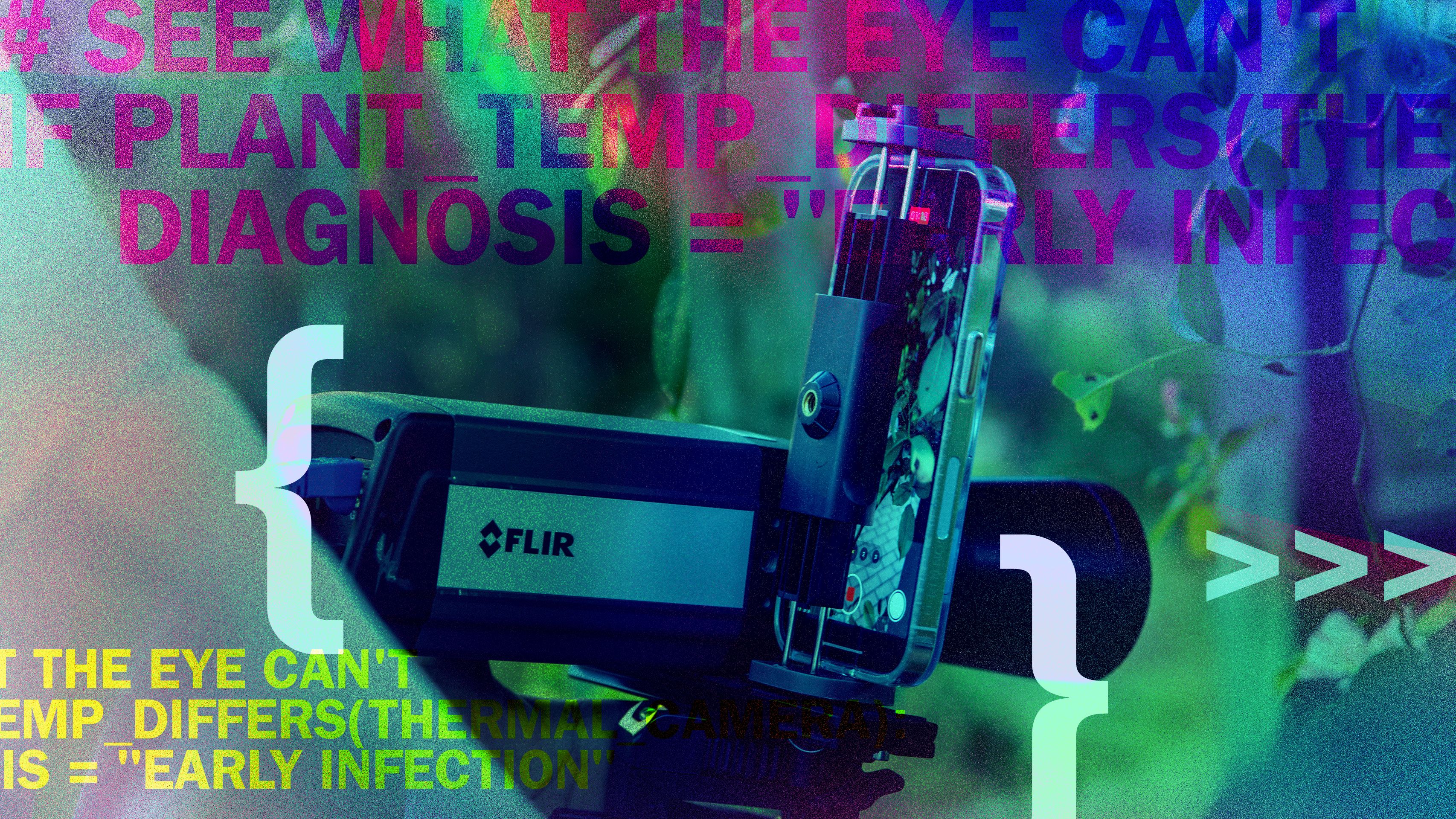

The same principles of automated image analysis are being applied to plant disease detection by the VIPR agricultural robotics team. Focused on rose rosette disease, a growing threat to Georgia’s roses, students are using thermal imaging and machine vision to try to detect the disease before visible symptoms appear. The team spent the fall semester collecting data at UGA’s Trial Gardens, part of the CAES Department of Horticulture, examining infected and healthy plants to see whether temperature differences could indicate early infection.

Rose rosette disease, caused by a virus spread by microscopic mites, is devastating to cultivated roses, leading to distorted growth, excessive thorns and, eventually, plant death.

“It’s been exciting to build on past work and apply computer vision to a real-world agricultural problem,” said biological engineering major Naman Kumar. “There’s great potential for this to help farmers detect disease early and act faster.”

To make data collection easier, the team built a small robot that can be equipped with a thermal or RGB camera to scan rose bushes more efficiently. The robot uses omnidirectional wheels, allowing for greater maneuverability in tight spaces and over uneven terrain. With a motor system tailored for stability and flexibility, it can also navigate low-lying foliage.

Moving forward, they hope to develop a machine-learning model that can predict the spread of rose rosette disease, giving farmers a crucial head start in managing outbreaks.

VIPR student Angilbert Baraka, a computer science and mathematics major, initially worried about how farmers would react to experimental tools being used on their crops. By fall semester's end, his perspective had shifted.

“As technology becomes more complex, people often think it’s going to replace traditional ways of life,” Baraka said. “VIPR showed me that technology can actually integrate with agriculture in ways that add value.”

Building on promising initial findings, the team is refining the research for larger-scale testing.

Detecting floor eggs

The third agricultural robotics sub-team, led by Assistant Professor Guoming Li of the Department of Poultry Science, is devising a robot to help poultry producers reduce waste and save labor.

In commercial egg production and processing — especially for producers who use cage-free systems — floor eggs, also called mislaid or system eggs, are eggs laid outside designated nest boxes.

These eggs pose a problem for farmers because they are more likely to become dirty or contaminated, increasing the risk of food safety issues. They also reduce efficiency, as workers must scan the barn, retrieve the eggs, and then inspect them for damage, taking time away from other essential operations.

Automated egg collection systems can continuously monitor the barn, quickly locating and retrieving floor eggs before they become too contaminated or damaged. By minimizing human traffic in the barn, robots can also reduce stress and improve overall welfare for the flock.

From left, VIPR students Satchit Seth, Nakyia Lezin-Bessard and Wissam Fekir stand behind graduate researcher Aravind Mandiga and Assistant Professor Guoming Li in front of a mural at the Poultry Science Building. (Photo by Lavi del Carmen Astacio)

From left, VIPR students Satchit Seth, Nakyia Lezin-Bessard and Wissam Fekir stand behind graduate researcher Aravind Mandiga and Assistant Professor Guoming Li in front of a mural at the Poultry Science Building. (Photo by Lavi del Carmen Astacio)

“Integrating machine learning with precision agriculture practices allowed the robotic system to adapt to varying environmental conditions, ensuring reliable performance in detecting eggs scattered throughout the facility,” said Satchit Seth, a computer systems engineering major working on the project.

However, using robots to collect floor eggs presents several challenges. Grip strength must be carefully calibrated — too much pressure can crush the egg, while too little results in dropped or uncollected eggs. Depth perception and object recognition are also difficult to perfect, as the robot must accurately detect and grasp eggs without missing them.

Li’s VIPR students are fine-tuning critical aspects of floor egg collection, including electrical and electronics engineering major Lezin, who devised a prototype retrieval arm using a pair of modified kitchen tongs.

Mechanical engineering major Wissam Fekir is working with a specialized RGB depth camera, which provides both depth and color data to enhance the robot’s egg-sensing capabilities.

A new era of VIPR

Arthur Edison, a professor and GRA Eminent Scholar in the Franklin College of Arts and Sciences who helped bring the VIPR concept to UGA in 2016, sees the growing program as a valuable tool both for providing undergraduate research experience and preparing graduate students for careers.

“I love that VIPR students get a more formalized training rather than just ‘here’s the pipette, here’s this instrument.’ They get context and training in an area they are interested in,” Edison said.