Equipment

-

Use this publication to calculate planting densities, fertilizer application rates, sprayer calibration, and soil amendment applications using unit conversions. We demonstrate the “raw math” behind common calculations to provide you with the tools for solving any equation using simple addition, subtraction, multiplication, and division. No longer will you be dependent on having production guides, fertilizer charts, planter manuals, and spray nozzle catalogs to tell you what to do.

Alton N Sparks, Wesley Porter, Ted McAvoy, Luan Oliveira, and Manisha Kumari

|

-

Spinach (Spinacia oleracea) is an important nutrient-dense leafy green, and its annual per capita consumption has significantly increased over the past decades. Spinach production in Georgia has experienced significant growth in the last few years, with over $400M in annual value, ranked first among all the other leafy green crops. Field spinach production is labor intensive, and the cost of weed management, harvest, and post-harvest accounts for 56% of the production cost. With the advantages of controlled environment agriculture in reducing labor costs and increasing production value with an extended growing cycle, hydroponic spinach has been gradually accepted and planted on a large scale.

Spinach is a cool season crop typically seeded during early spring or early fall. Summer season is often skipped because of pressure from insects, diseases, and weeds. Additionally, the optimal temperature for spinach seed germination is 65-70°F (18-21°C), and for spinach growth is 60-77°F (15-25°C). However, there is the possibility to grow spinach during summer in the greenhouse using a deep water culture hydroponics system that can minimize these pressures by focusing on heat-tolerant cultivar selection, germination improvement, and optimal hydroponic system implementation.

Rhuanito Soranz Ferrarezi and Kuan Qin

|

-

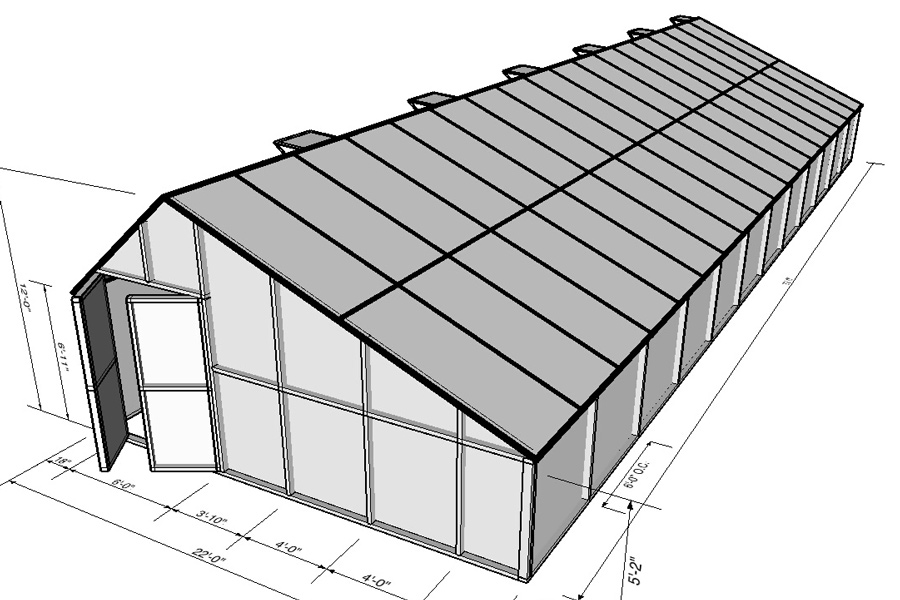

This publication describes how a passive solar greenhouse was constructed using an earthen wall and water barrels for heat retention. The benefits and potential pitfalls of such a structure are discussed. Additional authors include Alexandra Williams, Syngenta, U.S.A, and Krista Jacobsen, Department of Horticulture, University of Kentucky.

Timothy Coolong

|

-

High levels of dust in cage-free poultry house air can carry airborne microorganisms and endotoxins that, once inhaled, may trigger respiratory diseases in animals and/or their caretakers. Mitigating dust levels is imperative to protecting the health and well-being of the animals and their caretakers and improving the environmental stewardship of cage-free layer farms. Studies have concluded that good manure management and proper ventilation can alleviate dust problems. Mitigation strategies have various levels of effectiveness, but some are cost prohibitive. Selecting the right dust control strategy should consider poultry types, housing design, local climate, and litter/bedding management strategies.

Casey W. Ritz and Lilong Chai

|

-

Pulse width modulation (PWM) technology is becoming a standard option on most new agricultural sprayers because of its ability to precisely regulate both flow rate and pressure over a wide range of travel speeds. This publication provides information on nozzle selection for sprayers equipped with PWM technology, including how to use PWM nozzle selection/tabulation charts, other useful online tools, and considerations for effective pesticide applications.

Simerjeet Virk

|

-

C 1208

Chainsaw Chains and Bars

The action end of a chainsaw, or the part that cuts, is made of the bar and the chain. Chainsaw chains come in many sizes and configurations and not all saws can handle all bars. To make the right choices for the job, a saw operator should be aware of the cutter type, pitch, gauge, and cutter configuration when purchasing a chain or a chainsaw.

Josh Fuder

|

-

Irrigation systems are used by farmers and homeowners to supply supplemental

water to their crops. At the end of the growing season, the irrigation system should be checked and winterized to maintain proper operation for the coming season.This publication provides a list of suggested things that should by done on both drip and center pivot systems to help protect them during the winter months.

Gary L. Hawkins

|

-

Spinner-disc spreaders are commonly used for applying lime and fertilizer to

agricultural fields. Uniform and accurate application of lime and fertilizer is essential. The

performance failures of agricultural materials can be directly related to improper and uneven

application, careless equipment operation, and the separation of blended material due to size

and density differences. The uneven distribution of lime and fertilizer can reduce yields. Effects

of uneven lime or fertilizer distribution are most notable in fields that are low in soil fertility,

because the response to applied nutrients is greatest on these soils.

Proper setup and calibration of application equipment is important to assess its performance and

attain satisfactory results. Even new and well-maintained equipment needs calibration checks

regularly before and during the growing season. This is especially important when changing

from one type of material or blends to another, when changing application rates, and when

altering speeds or other operating conditions.Paul E. Sumner and Simerjeet Virk

|

-

This publication highlights some of the ongoing research into using SSDI in organic vegetable crop production. SSDI facilitates cultivation without harming drip tubing and limits surface soil wetting, which may also reduce weed pressure. Prior research has shown that SSDI offers some advantages over surface-placed drip tubing in conventionally grown crops (Coolong, 2016).

Timothy Coolong, Nicholas Tuschak Basinger, Kate Cassity-Duffey, and Ted McAvoy

|